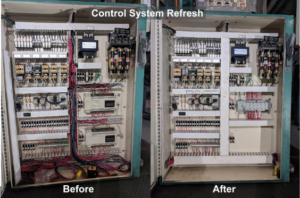

Breen Machine improves efficiency and maintainability of a client’s part handling system with a custom software redesign

Summary

An almost-finished part handling system was abandoned by the original team and in a barely maintainable state. The decision was made to salvage the usable code and rewrite the rest. The Breen Machine team solved our client’s problem with a software redesign to improve efficiency and maintainability of the system.

Key Benefits

- Maintainable program code

- Less downtime for troubleshooting

- Designed to have room for growth

Technologies used

- Allen Bradley RSLogix 5000

- Allen Bradley Emulate

- Allen Bradley FactoryTalk Studio

The Breen Machine Solution: Software Redesign

A mostly functional conveyor system was abandoned by the original developing team due to its complexity and cumbersome program structure. The end user purchasing the equipment wanted more efficient part handling, but the program was too confusing to tweak one part without fear of breaking something else. Even debugging simple process quirks was a challenge. Our client asked us to complete the job and ideally make the code more maintainable for their in-house team.

An analysis of the code revealed a highly duplicative program structure. Each conveyor had custom logic written for it, leaving a prevalence of copy/paste mistakes, typos, and inconsistencies. Fortunately the IO (input/output) programming was largely working so that was salvaged, but everything else needed to be scrapped and rewritten. To add to the challenge, this line was being used by production, so we needed to rewrite the program offline. Then production would shift schedule to allow us Friday through Monday to make it work. If the implementation took longer than that, it would interfere with production goals and customer profit. That was a tight time-frame for automation of this magnitude.

The basic logical system was written first along with a graphical simulation of product flow along the conveyor lines. This allowed us to debug and demonstrate basic functionality without using precious machine time. After approval from the customer, this new program was tied into the existing IO logic. When all was ready the system was installed, tested, and tweaked over the chosen weekend.

What originally took 5-6 people almost a year to “complete” was rewritten and improved in less than two months by one of Breen Machine’s talented programmers. In addition, over 6,000 rungs of ladder logic were removed, replaced by about 300 rungs of thoughtful, efficient code.

The end result is a much smaller, more navigable code base that the client can maintain and debug, resulting in fewer service calls and less downtime. Is a poorly written program making life difficult? Let us know how we can help.

About the Author

David is a driven problem solver with a background in PC application and web development. He thrives on challenging tasks and tight deadlines, generally preferring high-pressure projects and living out of a suitcase. When he’s not working 100 hour weeks he can usually be found in the gym or the local pool hall, almost certainly making new friends.