Summary

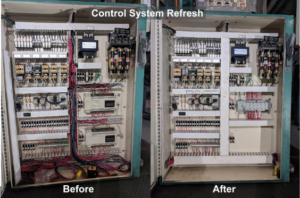

A small manufacturer of plastics had the in-house expertise to upgrade their hardware, but not to program it. Breen Machine Automation Services advised on the electrical design and programmed the changes.

Key Benefits

- Grew in-house expertise

- Extended the useful life of the equipment

- Increased system flexibility

- Reduced cost by leveraging internal resources

Technologies used

- Allen Bradley CompactLogix

- Allen Bradley Servo

- Allen Bradley PanelView HMI

The Breen Machine Solution

A small manufacturer of plastics based in Wisconsin had two aging assembly machines. The glue stations specifically were struggling to keep up with quality and product variety demands. The company had the in-house resources to manage the mechanical design of a replacement glue station but didn’t have the controls expertise, so they reached out to Breen Machine. The SLC500 PLC was too old to handle a modern servo drive, so it was replaced with a CompactLogix. We consulted on the key electrical details while they designed it, then we programmed and commissioned the new stations. The new glue station had a dedicated HMI allowing product selection, glue pattern adjustment, and station troubleshooting. We powered the first one up separately from the main equipment to debug the system, which allowed us to install and start it up with minimal downtime. Breen Machine’s customized approach allowed our customer to reduce costs compared to a fully outsourced solution.

In addition to the immediate benefits, our support added lasting value. Our customer was able to approach an intimidating project with confidence and further develop their in-house expertise, which continues to support their internal projects.

Could you do more with your automation if you just had access to the right expertise? Let us know how we can help.

About the Author

Jon is an engineer, entrepreneur, and teacher. His passion is creating and improving the systems that enhance human life, from automating repetitive tasks to empowering people in their careers. In his spare time, Jon enjoys engineering biological systems in his yard (gardening).