Breen Machine upgrades a PLC, recording the process for educational use

Key Benefits

- Easy process for the end user

- Maintainable hardware

- Recorded the process for education

Technologies Used

- Allen Bradley Micro800 PLC

- Allen Bradley Connected Components Workbench

The Breen Machine Solution

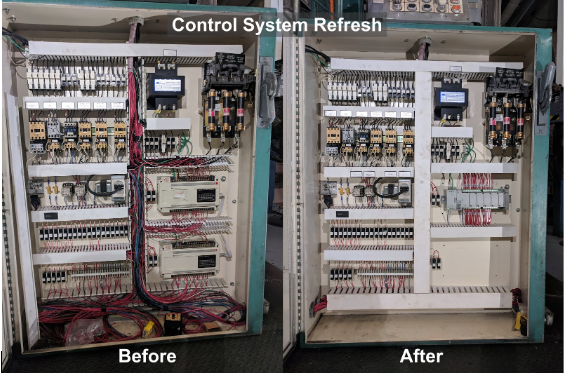

A depalletizing machine had an obsolete PLC and IO (Allen Bradley SLC150). It could no longer be replaced if it broke, and was already showing signs of degradation.

Breen Machine’s goal is to support people in their roles in industry, and we saw a two-fold opportunity in this project:

1) Upgrade the system: The PLC was quite old, and we had to call in a favor to get a laptop and cable to connect with it. There was no automated migration method, so the whole program was rewritten for the new PLC. After that, it was a simple process of removing the old hardware and installing the new. Breen Machine is well-versed in PLC upgrades and the whole process went smoothly. The entire upgrade took two days of preparation, two days on site, and cost less than $5,000.

2) Record the process: We’re always looking for opportunities to share our knowledge and experience. This customer was gracious enough to let us record the process to share. Watch on our YouTube channel for this free training video.

Do you have an aging control system you can’t support anymore? Get in touch. Upgrading is easier than you think.

About the Author

Jon is an engineer, entrepreneur, and teacher. His passion is creating and improving the systems that enhance human life, from automating repetitive tasks to empowering people in their careers. In his spare time, Jon enjoys engineering biological systems in his yard (gardening).