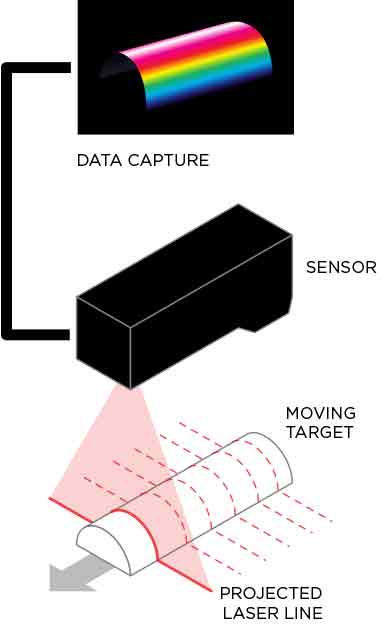

Breen Machine Provides Custom 3D Inspection Solutions for Paper Industry

Summary

A company in the paper industry wanted to improve product inspection but didn’t have the resources in-house to support the project. Breen Machine developed a custom PC application to work with a 3D scanner. The custom 3D inspection project led to big improvements in quality control and process monitoring, and we continue to develop new features to expand on these benefits.

Key Benefits

- Inline 3D inspection gives immediate results

- Process can automatically stop before problems get out of hand

- Process insights are enabled by large-scale data capture

Technologies Used

- Visual Studio

- PC

- LMI laser profiler

- LMI SDK, Hexsight tools

Conducting a 3D inspection is often a difficult task. Adding a third dimension adds complexity, and the built-in tools aren’t yet as easy or useful as their 2D counterparts, so custom programming is often required. Our customer has a talented R&D department but didn’t have enough resources to dedicate to this project. Breen Machine started by clarifying long- and short-term direction, and developing a prototype of the simplest form of the 3D inspection needed. This was a great proof of concept and gave us a foundation for testing different methods and adding features.

The Breen Machine Solution

Our customer’s team is insightful and creative about their process, always pushing the limits of what can be done. We’re proud to continue to develop this tool with them, which is now in use in multiple countries. This is a long-term relationship that we feel has been very rewarding on both sides; we’ve had the chance to learn from each other and build some great tools together.

Some examples of functionality:

- Detect location of hundreds of key features

- Measure key features

- Measure spacing and arrangement

- Perform statistical analysis

- Determine pass/fail based on user-defined parameters

- Log all results, with full scans of failures for later analysis

About the Author

Jon is an engineer, entrepreneur, and teacher. His passion is creating and improving the systems that enhance human life, from automating repetitive tasks to empowering people in their careers. In his spare time, Jon enjoys engineering biological systems in his yard (gardening).